Laminators for CFRP / GFRP composite materials made of nickel shell technology and their application in the aerospace industry

Laminating devices for CFRP / GFRP composite materials made of nickel shell technology

CDM-TECH and laminating devices for CFRP / GFRP composite material made of nickel shell technology

As the only technology provider for laminating devices for CFRP / GFRP composite materials made of nickel shell technology in China, CDM-TECH is constantly working on further developing and optimizing the core technologies of laminating nickel shell tools. Composites made with laminating nickel shell tools have stable material properties in terms of thermal fatigue resistance, high temperature resistance, corrosion resistance, impact resistance and creep resistance, and can be used for a long time in extreme environments, especially in harsh environments with high temperature oxidation and gas corrosion. The comprehensive properties of these composite materials are excellent. CDM-TECH has optimized several processes in the production of laminating nickel shell tools and thus enables considerable savings in production time and costs.

Compared to conventional technology for the production of CFRP / GFRP composite materials, laminating devices made of nickel shell technology have the following advantages:

- ●Lower manufacturing costs for thin-shell parts

- ●Realization of complex curved surface parts

- ●Smoother surface

- ●Greater dimensional accuracy

Advantages for the customer through the use of CDM-TECH laminating devices for CFRP / GFRP composite materials made of nickel shell technology

-

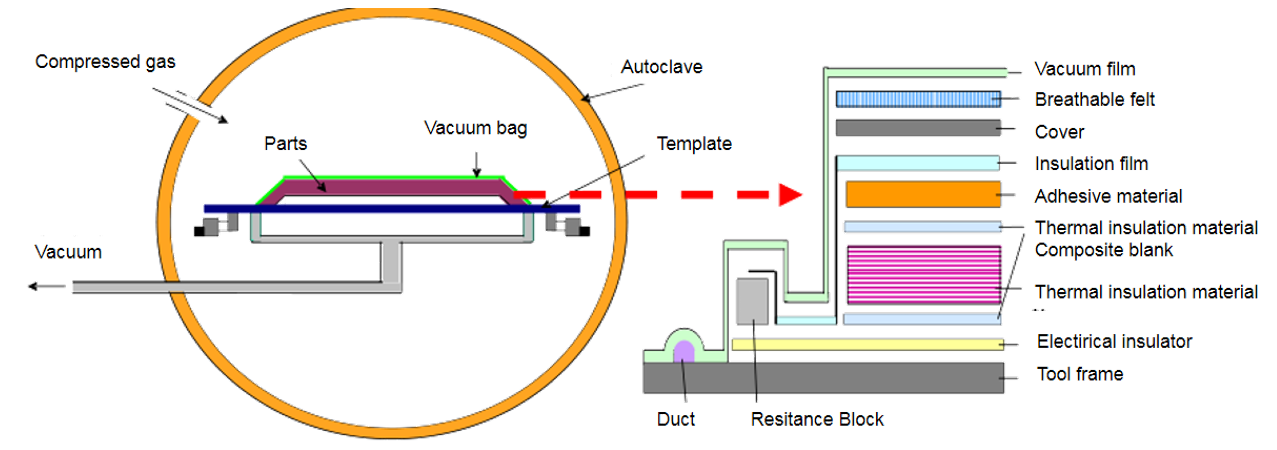

●Fast heat transfer

The heat transfer rate is three times higher than that of tool steel, which means that the temperature in the autoclave can be increased or decreased more efficiently.

-

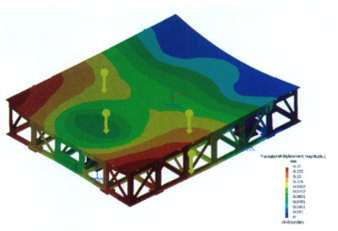

●High dimensional stability

Good mechanical properties and performance with repeated heating processes.

-

●Easy processing

For products with a high mass, different wooden models can be manufactured separately and then combined. Processing is no longer restricted to the size of NC processing machines.

-

●Corrosion resistance

Resistant to acidic and alkaline corrosion, rustproof when used under extreme conditions.

Production of CDM-TECH laminating devices for CFRP / GFRP composite materials made of nickel shell technology

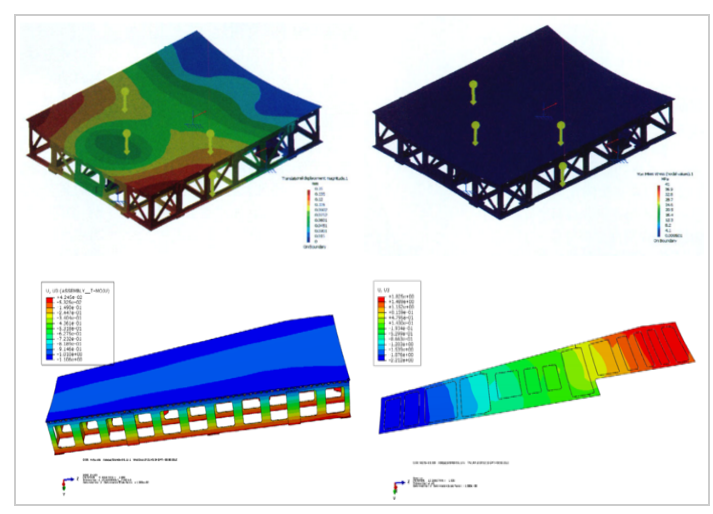

1. Simultaneous Engineering, Construction and Analysis of Aerospace Projects

CDM-TECH is a specialist in simultaneous engineering

- ●Customer-oriented construction

- ●Design-oriented construction

- ●Production-oriented construction

- ●Process-oriented construction

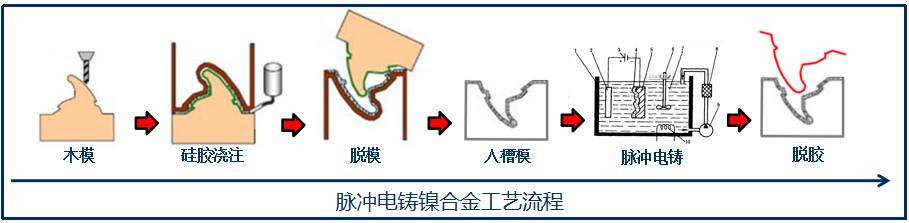

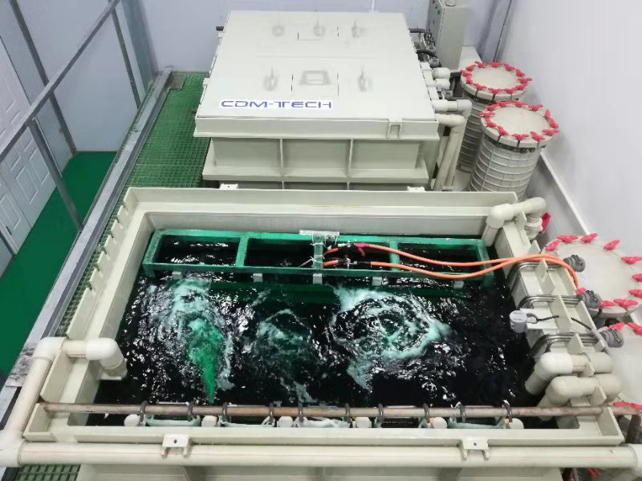

2. Production and processing of nickel shell tools

Nickel shell tools from CDM-TECH

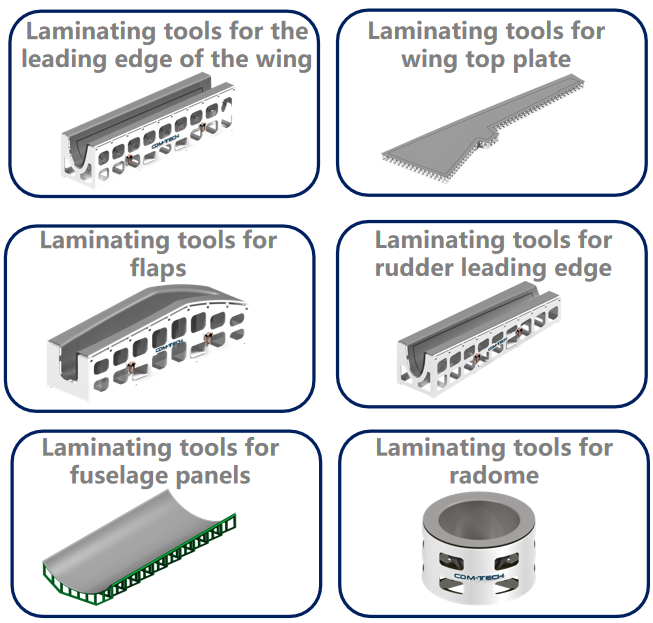

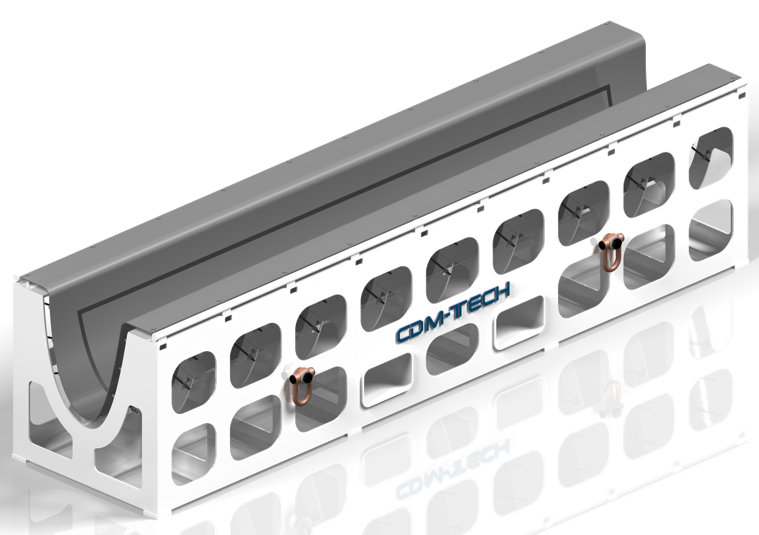

Laminators for CFRP / GFRP composites and other nickel aircraft parts

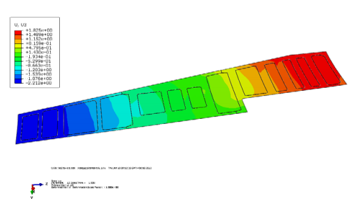

1.Wing leading edge + laminating devices for CFRP / GFRP composite materials made of nickel shell technology

- ●Flexible adjustment of the opening size during production

- ●The plate consists of a galvanized nickel shell, which has good mechanical properties and thermal conductivity

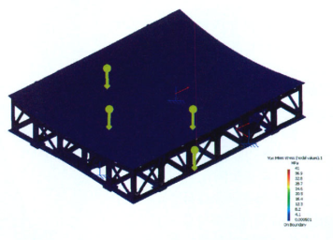

- ●The welded frame structure ensures the overall strength

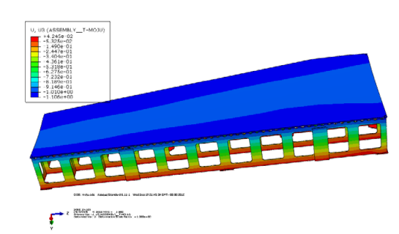

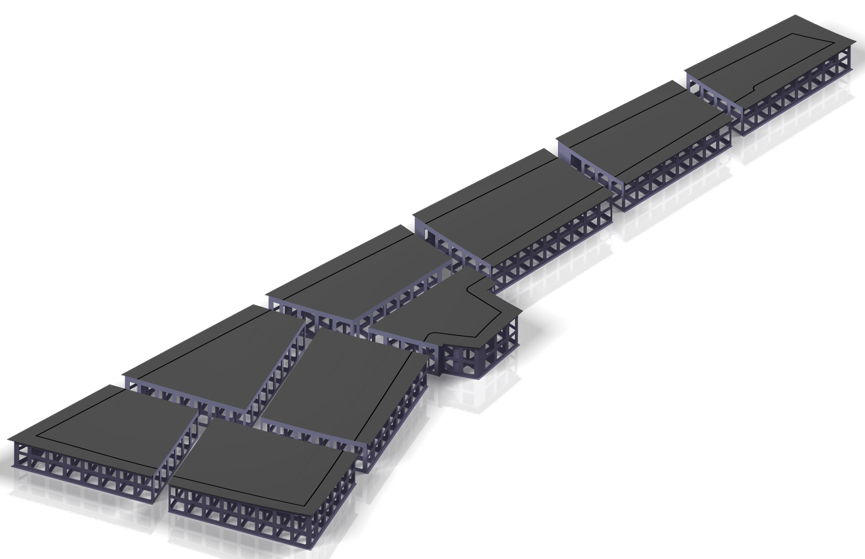

2.Wing plate + laminating devices for CFRP / GFRP composite materials made of nickel shell technology

- ●The plate has a splice structure that can effectively compensate for thermal expansion and contraction

- ●The plate has good mechanical properties and thermal conductivity

- ●The frame structure ensures the overall strength

3.Aircraft parts made of CFRP / GFK composite material