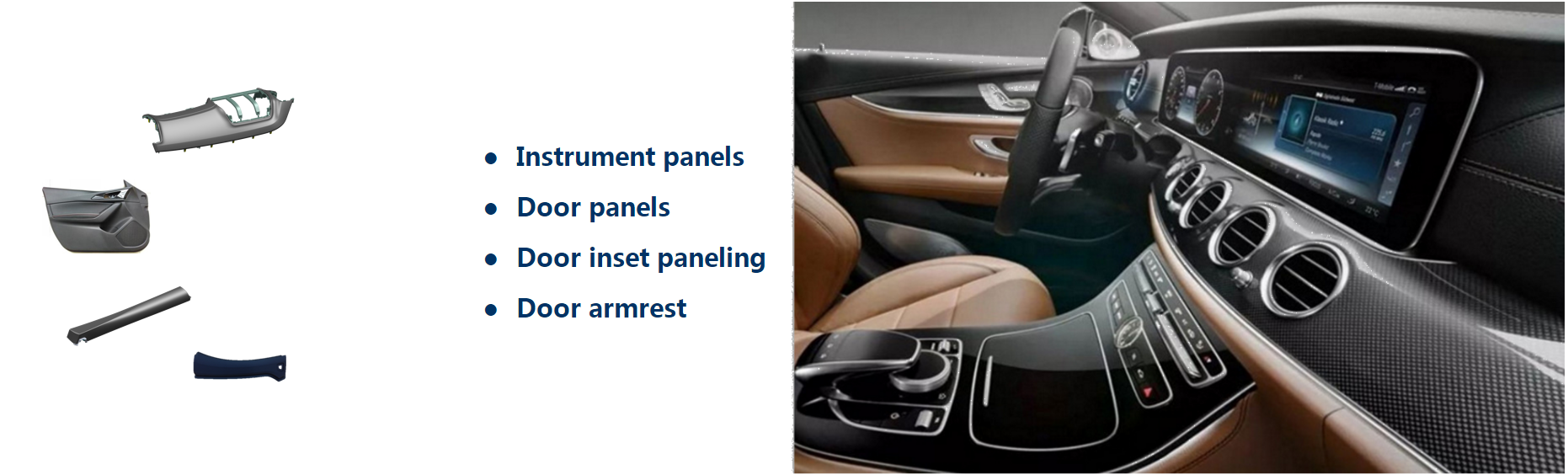

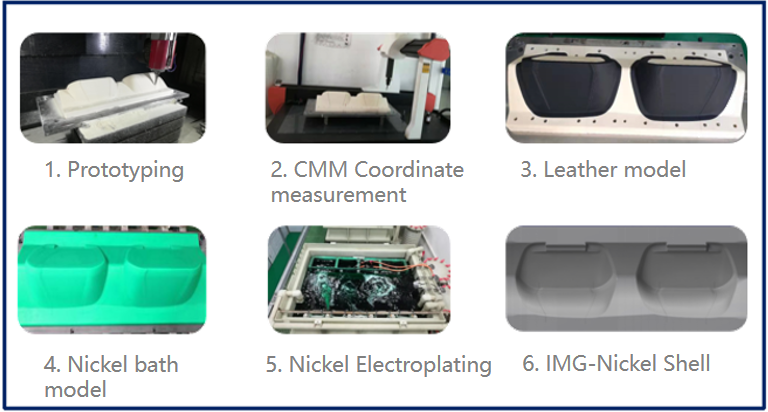

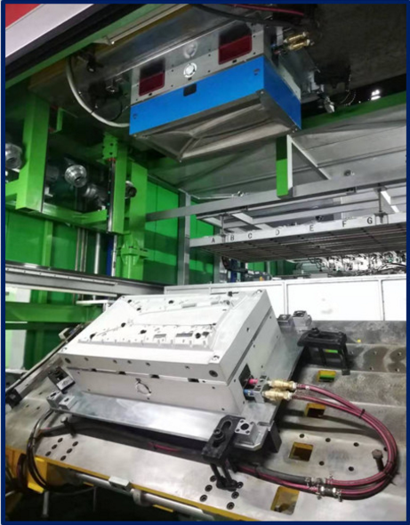

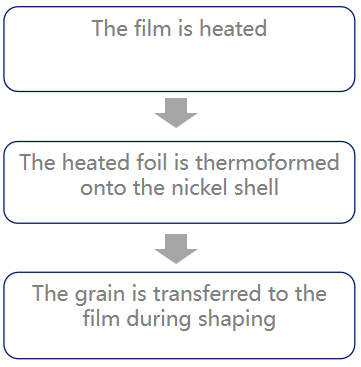

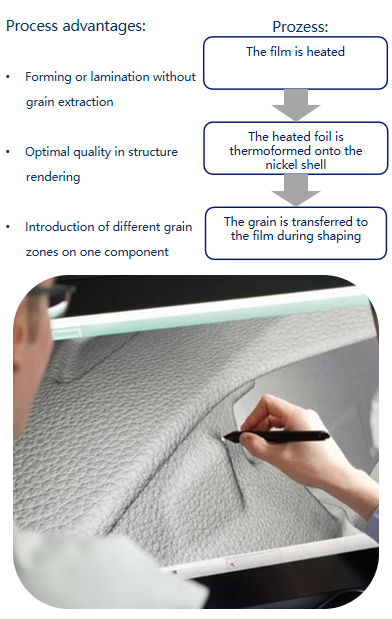

The IMG (In-Mold Graining) process, together with negative embossing using porous and surface-textured nickel tools, offers an economical alternative to ensure optimal reproduction of the desired structures. IMG tools are therefore ideally used in the processing of non-grained foils for the production of e.g. instrument panels, door panels and for vehicle interiors.

Process advantages:

- ● Forming or lamination without grain extraction

- ● Optimal quality in structure rendering

- ● Introduction of different grain zones on one component

EN

EN

DE

DE

JPN

JPN